Getting back to work and COVID-19 compliance

As the Government looks to slowly start getting us back to work - there will be (and already are) many questions on what individual companies should do.

The general guidance that has been issued is very helpful but may not cover your individual requirements and anxieties. Consider whether you need additional help to determine what is necessary for your business.

Next Steps

All companies have a duty of care to look after their employees’ health. The Health & Safety Executive and Local Authorities will be looking to undertake random inspections to ensure the Risks from COVID-19 have been assessed and are being controlled by businesses.

Before returning, ensure your assessment is complete and the new way of working has been agreed and communicated with your workforce. Nobody wants to see their business, their employees, their families or their customers impacted by this disease. Communication will be key to prevent misinformation and promote sustainable safe and efficient working.

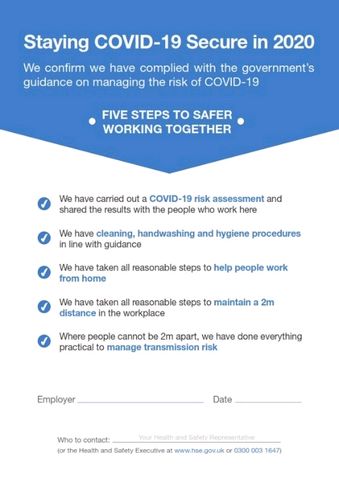

COVID Secure

All risk assessment findings need to be communicated. Furthermore, there is a Government Certificate to sign and display to show you have sufficiently addressed the concerns that COVID-19 raises. Businesses are urged to consider sharing the findings of their assessment on their website and, where you have over 50 employees this will be expected.

Getting Help

If you require any help or guidance in these strange times, we continue to work and are available to help with COVID-19 compliance. We are currently involved with various clients in producing procedures and business specific risk assessments. With our background in laboratory containment facilities and knowledge of biological hazards this is where our heart lies.

We are not just reserved for laboratories. We have been working hard with new and old customers alike in offices, maintenance services, self-employed whom work in other people’s properties and construction businesses. If you need any assistance, please feel free to reach out on 01223 265622 or Doates@healthsafetyworks.co.uk

Links to Guidance

https://www.gov.uk/guidance/working-safely-during-coronavirus-covid-19

https://www.hse.gov.uk/news/working-safely-during-coronavirus-outbreak.htm